Why Choose a Professional Cable Ties Manufacturer Like DIFVAN for Your Wiring Needs

Updated: 29-Dec-2025

96

In today’s fast-evolving industrial and electrical landscape, efficient and reliable cable management solutions are crucial. Whether it’s organizing wiring in large construction projects, securing cables in automotive manufacturing, or protecting electrical installations in harsh environments, cable ties are fundamental components that ensure safety, efficiency, and durability. When it comes to sourcing these essential products, choosing a professional cable ties manufacturer rather than a reseller or generic supplier can make a significant difference in quality, performance, and overall project success. DIFVAN is recognized globally as a leading manufacturer offering premium cable ties that meet diverse industry demands through innovation, quality control, and customizable solutions.

The Critical Role of a Cable Ties Manufacturer in Your Supply Chain

The value of working directly with a cable ties manufacturer lies in their full control over the manufacturing process. From selecting high-grade raw materials to employing advanced production technology and rigorous quality inspections, manufacturers ensure every product batch meets stringent performance standards. Unlike distributors or third-party sellers who depend on external sources, a dedicated manufacturer guarantees consistent product quality, reliable availability, and technical expertise.

This level of control becomes essential when cable ties are used in applications where failure could result in safety hazards or costly downtime. Professional manufacturers understand these challenges and design their products to withstand environmental stresses such as temperature extremes, UV exposure, chemical contact, and mechanical strain.

Premium Material Selection and International Compliance

High-quality cable ties start with premium materials. Most reliable manufacturers utilize nylon 6/6, renowned for its exceptional strength, flexibility, and resistance to abrasion and chemicals. For applications requiring enhanced durability, stainless steel cable ties offer superior corrosion resistance and tensile strength, making them ideal for outdoor, marine, and industrial environments.

Beyond material choice, adherence to global regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) ensures products are safe for users and environmentally compliant. Choosing a cable ties manufacturer who prioritizes these certifications guarantees products suitable for worldwide distribution and various industry standards.

Extensive Product Range Tailored to Diverse Applications

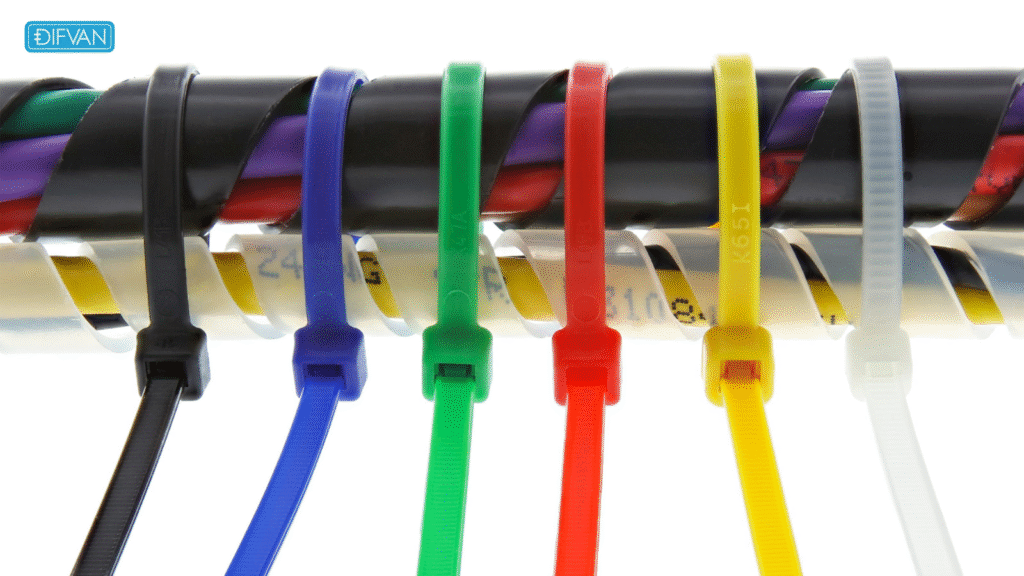

No two wiring projects are alike, which is why a professional cable ties manufacturer offers an extensive product lineup. This includes general-purpose nylon cable ties in various sizes and colors, heavy-duty cable ties engineered for demanding mechanical loads, UV-resistant ties for prolonged outdoor use, and stainless steel variants designed for extreme conditions.

Moreover, manufacturers often supply specialized solutions such as releasable cable ties for temporary bundling, marker ties for easy identification, and flame-retardant options for electrical safety compliance. This variety simplifies sourcing, allowing customers to find the precise cable tie suitable for their unique requirements without compromising on performance.

Customization Capabilities and OEM/ODM Services

One of the standout advantages of partnering with a cable ties manufacturer is the ability to customize products according to specific needs. This can include tailoring lengths, widths, colors, tensile strengths, and packaging styles. Many manufacturers also offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing clients to brand products with their logos, create unique packaging, or develop entirely new cable tie designs.

Such flexibility empowers distributors, contractors, and businesses to differentiate themselves in competitive markets while ensuring consistent supply and quality from a trusted factory partner.

Advanced Manufacturing Technology and Strict Quality Assurance

Leading manufacturers operate modern facilities equipped with automated injection molding machines, robotic handling, and advanced inspection tools. This investment in technology results in precise dimensional accuracy and consistent product characteristics that manual processes cannot match.

Quality control is embedded in every production stage, including raw material testing, in-process inspections, tensile strength verification, and final batch evaluations. Rigorous testing protocols minimize the risk of defects and enhance product reliability, building lasting trust with customers who depend on flawless performance in critical applications.

Competitive Pricing and Cost Savings Through Factory Direct Supply

By sourcing directly from a cable ties manufacturer, buyers can benefit from more competitive pricing compared to purchasing through intermediaries or wholesalers. Manufacturers optimize production efficiency, reduce overhead, and leverage economies of scale to offer attractive prices without compromising quality.

This cost advantage is especially important for bulk buyers and large-scale projects, where price fluctuations can significantly impact budgets. Factory-direct supply also ensures greater transparency in order fulfillment and pricing consistency over time.

Reliable Production Capacity and Global Logistics Expertise

A professional manufacturer is equipped to handle both small and very large volume orders without sacrificing delivery timelines or quality. With streamlined production planning and inventory management, manufacturers meet urgent requests and support ongoing project demands.

Many cable ties manufacturers, including DIFVAN, have extensive experience exporting worldwide. They understand international shipping regulations, packaging requirements, and documentation processes. This expertise reduces delays and ensures products arrive safely and on schedule, supporting customers’ operational continuity.

Wide Industry Applications and Proven Performance

Cable ties manufactured to high standards find use in a broad spectrum of industries. Electrical contractors use them for organizing complex wiring systems. The automotive sector relies on durable cable ties for harnessing wires that endure vibration and temperature fluctuations. Construction projects use cable ties for securing cables and pipes efficiently, while renewable energy installations demand corrosion-resistant ties that perform outdoors.

By selecting products from a specialized manufacturer, customers gain access to solutions designed to meet these diverse needs, backed by engineering knowledge and tested performance data.

Why DIFVAN Is a Trusted Name in Cable Ties Manufacturing

With over a decade of experience, DIFVAN has established itself as a reliable factory specializing in wiring accessories, including a comprehensive range of cable ties. Combining advanced production techniques, strict quality control, and responsive customer service, DIFVAN supports clients globally with durable, customizable cable ties designed for a variety of applications.

Their commitment to innovation and customer satisfaction makes them a preferred partner for businesses looking to secure high-quality wiring solutions with consistent supply and factory-direct pricing.

Conclusion

Selecting a professional cable ties manufacturer is more than just a purchasing decision—it is a strategic partnership that impacts the safety, efficiency, and success of your wiring projects. From premium materials and strict quality assurance to customization options and global logistics support, working directly with a manufacturer delivers unmatched advantages.

For businesses seeking reliable, high-performance cable ties combined with competitive pricing and expert support, DIFVAN represents a trusted choice. Partnering with an experienced manufacturer ensures your wiring needs are met with products engineered for durability, consistency, and long-term success.

Please Write Your Comments