Chemical Mask Usage and Top 10 Manufacturers : Ultimate Guide for Protection Against Harmful Chemicals

Updated: 27-Apr-2025

233

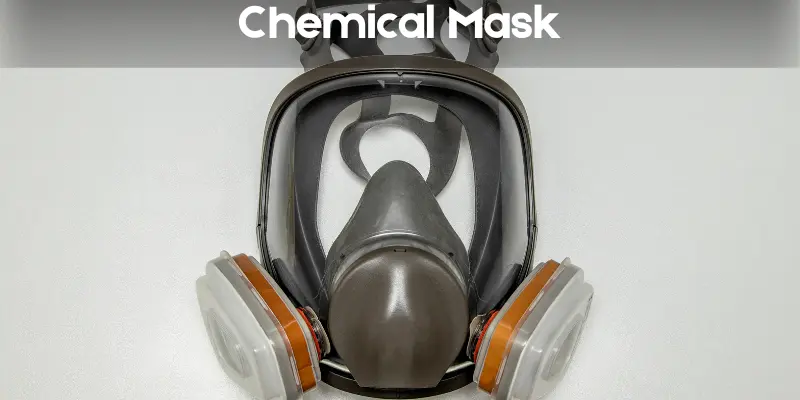

A chemical mask is a specialized piece of personal protective equipment (PPE) designed to provide respiratory protection for chemicals. It acts as a barrier between hazardous airborne particles and the wearer, ensuring safety from toxic environments. Whether you’re dealing with industrial chemicals, hazardous fumes, or chemical warfare agents, a chemical respirator is essential for survival and health. Over the years, the technology and design of these masks have evolved tremendously, catering to the needs of various industries and emergencies.

See further detail of topics in this Article

1.Back History of Chemical Mask

The concept of protective masks dates back to ancient times when people used wet cloths to shield themselves from smoke or dust. However, the modern chemical mask emerged during World War I, driven by the need to protect soldiers from chemical warfare gases like chlorine and mustard gas. The early designs were simple but laid the foundation for today’s advanced industrial safety equipment.

2. Who Invented the Chemical Mask?

The credit for inventing the first practical chemical respirator goes to Garrett Morgan, an African American inventor. In 1914, he patented a “safety hood” that provided respiratory protection against smoke, toxic gases, and chemicals. His invention revolutionized PPE for chemical exposure and is considered a milestone in occupational safety.

3. What Is a Chemical Mask?

A chemical mask is a type of respiratory protective equipment (RPE) specifically designed to filter, neutralize, or block harmful chemical substances from being inhaled or making contact with the face. These masks are used in settings where the air is contaminated with toxic gases, vapors, mists, fumes, or particulates that cannot be avoided through ventilation alone.

Important Distinction:

- A chemical mask is specifically focused on chemical threats.

- Not all respirators are chemical masks; some are only designed for dust, pollen, or biological hazards.

4. Differences Between Chemical Masks and Respirators

While often used interchangeably, there are important differences between chemical masks and respirators that you should understand, especially for proper selection and use.

| Aspect | Chemical Mask | Respirator |

|---|---|---|

| Purpose | Specifically designed for chemical vapor, gas, and fume protection. | Broader category that protects against particles, gases, vapors, biological hazards, etc. |

| Scope | Primarily focuses on chemical exposure. | Includes chemical, particulate (dust/mist), and biological exposure. |

| Types | Usually refers to full-face or half-face masks with chemical cartridges. | Includes air-purifying respirators (APRs) and supplied-air respirators (SARs). |

| Protection Level | High protection against specific chemical hazards. | Varies widely: some for dust (e.g., N95), others for chemicals (e.g., organic vapor respirators). |

| Common Examples | Full-face gas masks, organic vapor half masks. | N95 masks, P100 masks, full SCBA systems. |

| Standards and Certification | Must meet chemical-specific standards like NIOSH chemical ratings. | Different certifications based on hazard type (e.g., NIOSH, OSHA). |

| Use Case Example | Protecting against ammonia fumes, chlorine gas, solvent vapors. | Protecting against COVID-19, wildfire smoke, lead dust, or chemical vapors. |

Quick Summary:

- All chemical masks are respirators, but not all respirators are suitable for chemical exposure.

- Always match the mask/respirator type to the specific hazard you are facing.

5. Purpose of a Chemical Mask

The primary purpose of a chemical mask is to protect the wearer’s respiratory system and face from exposure to hazardous chemicals found in vapors, gases, fumes, and particulates. In many workplaces and environments — from laboratories and factories to home workshops — breathing in chemical contaminants can cause serious short-term and long-term health effects, including respiratory illnesses, poisoning, and even cancer.

1. Main Purposes of a Chemical Mask:

- Prevent inhalation of toxic chemicals:

Filters out harmful substances like organic vapors, chlorine gas, ammonia, pesticides, paint solvents, and acids before they enter the lungs. - Protect mucous membranes (eyes, nose, mouth):

Full-face chemical masks shield the eyes and sensitive skin areas from chemical splashes and vapors that can cause burns or irritation. - Maintain respiratory safety in hazardous environments:

Essential for workers in chemical plants, laboratories, spray painting, agricultural pesticide use, and emergency chemical spill response. - Ensure regulatory compliance and workplace safety:

OSHA, NIOSH, and other global safety organizations mandate proper respiratory protection in environments where chemical exposure risks exist. - Provide peace of mind:

Knowing that you are properly protected allows for better focus and performance in hazardous work or DIY tasks.

In Simple Terms:

A chemical mask serves as a life-saving barrier, filtering and blocking dangerous airborne substances that would otherwise directly harm your body.

6. Signs Your Chemical Mask Needs Immediate Replacement

A chemical mask will not protect you properly if it’s damaged, worn out, or compromised. Here are the top signs that mean you must immediately replace your mask or its parts:

1. Difficulty Breathing

- If breathing becomes noticeably harder, your filters or cartridges are likely clogged or saturated.

2. Detection of Chemical Smells

- If you start smelling vapors, gases, or chemical odors through the mask, it’s a clear sign that the cartridge or mask seal has failed.

3. Visible Damage

- Cracks, tears, warped seals, broken straps, or distorted facepieces indicate the mask’s structure is compromised.

4. Expired Cartridges or Filters

- Cartridges have a limited shelf life (typically 6 months to 5 years sealed, much less once opened).

- Always check the expiration date printed on the cartridge.

5. Mask Doesn’t Seal Properly

- If you can’t get a good seal during the fit test (positive or negative pressure test), replace or repair the mask.

6. Excessive Moisture or Mold Growth

- Masks exposed to high humidity without proper drying may grow mold inside — replace immediately.

7. Exposure to Extreme Contamination

- After chemical spills, fires, or exposure to unknown toxic environments, it’s safer to replace the mask and filters.

8. Manufacturer’s Usage Limit Reached

- Some manufacturers specify a maximum number of cleaning cycles or hours of service — respect these guidelines.

7. Chemical Mask Storage and Maintenance Checklist

Proper storage and maintenance are critical to preserve the integrity of your chemical mask. Here’s a simple yet effective checklist to follow:

1. After Every Use:

- Inspect for damage (cracks, tears, loose valves, broken straps).

- Remove filters/cartridges (if recommended by manufacturer).

- Wash the facepiece with mild soap and warm water (never use solvents).

- Rinse thoroughly and air dry away from direct sunlight and heat.

- Wipe down straps and valves carefully.

2. For Storage:

- Store in a sealed plastic bag or airtight container to protect from dust, chemicals, and moisture.

- Keep away from extreme temperatures and direct sunlight.

- Separate mask body and cartridges if storing long-term.

3. Monthly Maintenance:

- Perform a full fit check.

- Check the expiration date of all filters/cartridges.

- Inspect seals, valves, and head harness for any signs of aging.

- Test exhalation valve function — ensure smooth airflow.

4. Annual Maintenance:

- Replace any worn-out parts according to the manufacturer’s maintenance kit recommendations.

- Consider professional inspection if the mask is critical to high-risk work (e.g., chemical plants, fire rescue).

Quick Tip:

“A chemical mask is only as good as its condition. Treat it like life-support gear, not just a tool.”

8. Top 10 Mistakes People Make with Chemical Masks

Wearing a chemical mask doesn’t automatically guarantee safety. Many people unknowingly put themselves at risk by making simple mistakes.

Here are the top 10 mistakes to avoid:

1. Using the Wrong Type of Mask

- Not all masks protect against all chemicals.

- Mistake: Using a basic dust mask against toxic fumes or organic vapors.

2. Ignoring the Fit Test

- If the mask doesn’t seal properly, contaminated air will leak in.

- Mistake: Wearing the mask without performing a positive and negative pressure fit test every time.

3. Reusing Expired or Saturated Cartridges

- Filters have limited service life.

- Mistake: Continuing to use filters that are expired, saturated, or past their usage hours.

4. Poor Storage Habits

- Masks and filters degrade when exposed to sunlight, dust, moisture, or chemicals during storage.

- Mistake: Throwing the mask into a dusty toolbag or leaving it in a hot car.

5. Failing to Inspect Before Each Use

- Damaged masks provide little to no protection.

- Mistake: Trusting that the mask is fine without checking for cracks, broken valves, or missing parts.

6. Using the Mask Beyond Its Rated Capability

- Some masks are not meant for high concentrations of chemicals or oxygen-deficient environments.

- Mistake: Using an industrial chemical mask where a supplied-air system (SCBA) is needed.

7. Not Cleaning the Mask After Use

- Dirt, sweat, chemicals, and moisture can degrade seals and valves.

- Mistake: Wearing a dirty, contaminated mask the next time.

8. Wearing Facial Hair That Breaks the Seal

- Beards, stubble, or even thick sideburns can prevent a tight seal.

- Mistake: Not shaving when using a tight-fitting respirator.

9. Mixing Incompatible Filters

- Some people mistakenly attach different types of filters not designed for their specific mask model.

- Mistake: Using non-matching filters or stacking filters without manufacturer approval.

10. Assuming One Mask Fits All Situations

- Different tasks (pesticide spraying, chemical spills, lab work) require different cartridge types or mask models.

- Mistake: Relying on a single general-purpose mask for every hazardous environment.

Quick Safety Reminder:

“A chemical mask is NOT just an accessory — it’s your first line of defense between life and toxic exposure. Respect it, maintain it, and use it properly.”

9. Parts List of a Chemical Mask

A chemical mask consists of several critical components, each designed to ensure maximum protection, proper airflow, and wearer comfort. Here’s a detailed parts breakdown:

1. Main Parts of a Chemical Mask:

- Facepiece (Body):

- The main structure made of silicone, rubber, or thermoplastic.

- Covers either the mouth/nose (half-mask) or full face (full-mask).

- Seal/Gasket:

- Soft edges that ensure an airtight fit against the skin, preventing contaminated air leakage.

- Filters or Cartridges:

- Replaceable units that purify incoming air by trapping or chemically neutralizing harmful substances.

- Types: Organic Vapor, Multi-Gas, Particulate (P100).

- Filter Retainer:

- Holds the filters or cartridges securely in place.

- Inhalation Valves:

- Allow air to enter through the filters but prevent contaminated air from entering directly.

- Exhalation Valve:

- Allows exhaled air to escape without lifting the mask seal, reducing heat and moisture buildup.

- Lens (for Full-Face Masks):

- Clear, impact-resistant material protecting the eyes and ensuring good visibility.

- Strap System/Head Harness:

- Adjustable straps that secure the mask tightly but comfortably to the wearer’s head.

- Speaking Diaphragm (Optional, Full-Face Models):

- Allows clear communication while wearing the mask.

- Drinking Port (Optional, Tactical Models):

- Allows drinking without removing the mask, used in military or hazardous response.

10. Guide to Use a Chemical Mask

Using a chemical mask correctly is essential to ensure complete protection against hazardous chemicals. Here’s a step-by-step guide:

1. Step-by-Step Usage Guide:

- Inspect the Mask:

- Check for cracks, tears, or worn-out parts.

- Ensure valves, straps, and cartridges are intact.

- Select Appropriate Filters/Cartridges:

- Choose filters based on the specific chemical hazard.

- Attach cartridges properly — listen for a click or firm connection.

- Put on the Mask:

- Position the mask on your face (chin first for full-face masks).

- Pull the straps over your head and tighten them evenly.

- Ensure a snug, comfortable fit.

- Perform a Fit Check:

- Positive Pressure Test: Exhale gently; the mask should bulge slightly without leaking air.

- Negative Pressure Test: Cover filters, inhale gently; the mask should collapse slightly without leaking air.

- Wear Other PPE If Needed:

- Goggles, gloves, suits, or boots, depending on the task.

- Work Safely:

- Monitor for breathing difficulty, odor breakthrough, or dizziness — these may indicate mask failure or exhausted filters.

- Remove the Mask Safely:

- Move to a clean, safe area first.

- Remove by loosening straps without touching the face.

- Clean and Store Properly:

- Wash with mild soap and warm water.

- Air-dry completely.

- Store in a sealed container or clean bag, away from contaminants.

- Replace Cartridges Regularly:

- Follow manufacturer guidelines.

- Never reuse expired or saturated cartridges.

Pro Tip:

Never wait until you can smell chemicals through the mask — replace cartridges proactively based on usage hours or exposure level.

11. Difference Between Chemical Mask and Other Types

| Aspect | Chemical Mask | Other Masks |

|---|---|---|

| Purpose | Protection from chemicals, gases, and vapors | Dust, pollution, pathogens |

| Filtration Mechanism | Chemical cartridge respirator or filters | Particle filters |

| Coverage | Full-face or half-face | Mostly half-face or simple covers |

| Durability | Reusable or disposable | Mostly disposable |

| Certification | OSHA-approved chemical mask standards | Varies by type |

| Hazard Level | High-risk chemical environments | Low to medium hazards |

| Comfort | Heavier but secure | Lightweight but less protection |

| Examples | Multi-gas respirator, organic vapor respirator | Cloth masks, surgical masks |

| Emergency Use | Emergency chemical mask available | Not designed for chemical emergencies |

| Additional Protection | Often paired with anti-chemical face shield | Rarely paired with shields |

12. Uses of Chemical Mask

- Industrial chemical manufacturing

- Chemical spill clean-up operations

- Laboratory research work

- Handling toxic gases

- Working with chemical spray mask for painting

- Firefighting with chemical threats

- Agricultural pesticide spraying

- Hazardous waste management

- Military chemical defense

- Mining operations

- Oil and gas industries

- Water treatment plants

- Handling toxic fumes protection tasks

- Pharmaceutical production

- Chemical disaster response

- Medical emergency during chemical exposure

- Nuclear plant operations

- Demolition of contaminated buildings

- Air filtration training exercises

- DIY projects with strong chemicals

13. Types of Chemical Mask

- Full face chemical mask

- Half-face chemical respirator

- Chemical mask for painting

- Organic vapor respirator

- Multi-gas respirator

- Chemical warfare mask

- Emergency chemical mask

- Reusable chemical mask

- Disposable chemical mask

- Industrial chemical mask

- Chemical fume mask

- Gas mask for chemicals

- Protective face mask for chemical exposure

- Chemical protection mask for lab work

- Chemical safety mask for factories

- Chemical hazard mask for emergencies

- Air-purifying respirator with chemical filters

- Powered air-purifying respirator (PAPR)

- Self-contained breathing apparatus (SCBA) for chemical protection

- Military-grade CBRN chemical masks

14. How Does a Chemical Mask Work?

A chemical mask works by filtering harmful chemicals and gases from the air before they reach your lungs. It uses specialized chemical mask filters or cartridges filled with activated carbon, resins, and other absorbent materials that chemically react with or physically trap hazardous substances. Some advanced models even provide an independent air supply for maximum chemical inhalation protection.

15. Materials Used to Manufacture Chemical Mask

- Silicone rubber (for flexibility and comfort)

- Thermoplastic elastomers (TPE)

- High-grade plastics (for frames and shells)

- Polycarbonate (for face shields)

- Activated carbon (in chemical mask filters)

- HEPA filters (for fine particulate matter)

- Metal components (for valve systems)

- Cotton and polyester (for internal padding)

16. Importance of Chemical Mask

- Protects from hazardous chemical exposure

- Prevents inhalation of toxic gases

- Shields against airborne chemical splashes

- Ensures occupational safety

- Vital for chemical warfare preparedness

- Meets OSHA-approved chemical mask standards

- Mandatory in many industrial sectors

- Reduces long-term respiratory illnesses

- Enhances emergency response effectiveness

- Critical in laboratory environments

- Provides toxic fumes protection

- Used in agricultural chemical spraying

- Necessary during hazardous waste handling

- Supports military operations safety

- Protects during chemical plant accidents

- Reduces healthcare costs from exposure

- Enhances public health during chemical emergencies

- Protects eyes and face with full-face models

- Supports compliance with safety regulations

- Critical part of personal protective equipment (PPE) kits

17. Use of Chemical Mask: Past, Present, and Future

1. Past:

Chemical masks emerged during World War I to protect soldiers from deadly chemical weapons. Their early designs were rudimentary but laid the groundwork for modern respirators.

2. Present:

Today, chemical protection masks are sophisticated, lightweight, and highly efficient. Industries like manufacturing, pharmaceuticals, and emergency services rely heavily on these masks for worker safety.

3. Future:

Future chemical masks will incorporate smart sensors, real-time air quality monitoring, and self-cleaning filters, advancing the fight against hazardous chemical exposure with AI-powered PPE.

18. Best Chemical Mask for Hazardous Materials

When dealing with hazardous materials, choosing the best chemical mask is critical for safety, health, and regulatory compliance. Hazardous substances like acids, ammonia, pesticides, solvents, and biological agents require a high-grade chemical mask that provides full protection against airborne toxins, vapors, and particles.

1. Features of the Best Chemical Masks for Hazardous Materials:

- Full-Face Protection: Covers the entire face to protect eyes, nose, and mouth.

- Multi-Gas and Vapor Cartridges: Compatible with multiple filter types to handle a variety of chemicals.

- NIOSH Certification: Indicates compliance with strict safety standards.

- Tight, Secure Seal: Prevents leakage around edges.

- Durable Material: Resistant to chemical degradation and mechanical wear.

- Comfortable Fit: Adjustable straps and soft inner linings for long-term wear.

2. Top Recommended Chemical Masks:

- 3M Full Facepiece Reusable Respirator 6900

- Features a large lens for wide field of vision.

- Compatible with various cartridges for gases, vapors, and particulates.

- Honeywell North 7600 Series Full Facepiece

- Silicone facepiece for superior fit and durability.

- Used widely for chemical handling and hazardous material response.

- Avon Protection FM53 Multi-Role Respirator

- Military-grade respirator designed for extreme hazardous environments.

- Used by first responders and defense teams worldwide.

Important Tip:

Always pair the mask with the correct filter cartridges based on the specific hazardous material you are handling!

19. Chemical Mask for Industrial Use

In industrial environments — such as chemical manufacturing, painting, pesticide application, or metalworking — workers are often exposed to toxic gases, vapors, dust, and fumes. A chemical mask for industrial use must provide robust protection while being comfortable enough for extended shifts.

1. Key Characteristics for Industrial Chemical Masks:

- Half-face or full-face options based on exposure level.

- Interchangeable filters for different chemical hazards.

- Impact-resistant lenses (for full-face masks).

- High breathability to minimize fatigue.

- Compatibility with hard hats and other PPE.

- Maintenance-friendly (easy to clean and replace parts).

2. Top Picks for Industrial Chemical Masks:

- 3M Half Facepiece Reusable Respirator 7500 Series

- Silicone construction for extra comfort.

- Excellent for industrial painters, welders, and chemical handlers.

- MSA Advantage 3000 Full-Face Respirator

- Offers superior protection against a broad range of chemical threats.

- Highly durable with anti-fog lens.

- Draeger X-plore 3500 Series

- Professional-grade half-mask with twin filter design.

- Ideal for industrial maintenance, spraying, and chemical processing.

Pro Tip:

Regular fit testing and filter replacement are essential for ensuring ongoing protection in an industrial setting.

20. Top-Rated Chemical Respirators for Lab Work

Laboratories often involve working with concentrated chemicals, biological agents, solvents, and volatile compounds. A top-rated chemical respirator for lab work must ensure high protection without obstructing vision, communication, or dexterity.

1. What Makes a Good Lab Chemical Respirator:

- Lightweight and ergonomic design for precision tasks.

- P100 particulate filters combined with organic vapor cartridges.

- Low breathing resistance for ease during experiments.

- Clear communication valve (optional, for talking while wearing).

- Flexible compatibility with lab goggles and protective gear.

2. Best Chemical Respirators for Lab Settings:

- 3M 6000 Series Half Facepiece Respirator

- Lightweight, low-profile design.

- Compatible with a wide range of chemical and particulate filters.

- Moldex 9000 Series Full Face Respirator

- Frameless panoramic lens for clear visibility.

- Extremely easy to maintain and decontaminate.

- Honeywell Survivair Opti-Fit Tactical Respirator

- High-impact resistant face shield.

- Excellent for chemical, biological, and radiological lab environments.

Lab-Specific Reminder:

Lab respirators must also be chemical-resistant against accidental splashes and should allow fine motor control during experiments.

21. Chemical Mask for Home Use Against Fumes

Even at home, exposure to harmful fumes can occur during activities like painting, cleaning with strong chemicals, pest control, DIY repairs, or disinfecting spaces. A chemical mask for home use must provide reliable protection while being comfortable, lightweight, and easy to use.

1. Key Features for Home Chemical Masks:

- Lightweight and simple design — easy to put on and remove.

- Effective against organic vapors and chemical fumes (like bleach, ammonia, paints, pesticides).

- Good breathability for long periods of household use.

- Affordable and reusable — without complicated maintenance.

- NIOSH-approved for trust in performance.

2. Top Choices for Home Use:

- 3M 6502QL Rugged Comfort Half Facepiece

- Excellent for painting, chemical use, and pest control at home.

- Quick latch design for easy on and off.

- GVS Elipse P100 Respirator Mask

- Ultra-compact and lightweight, perfect for small projects.

- Offers P100 protection plus defense against fumes.

- Honeywell Half Mask Respirator 7700 Series

- Soft, flexible material for ultimate comfort.

- Great for household chemical fumes and dust.

3. Best Home Applications:

- Spray painting indoors

- Using bleach or ammonia-based cleaners

- Applying pesticides

- Handling solvents or varnishes

- DIY renovation or insulation work

Safety Tip:

Always ensure proper ventilation in the workspace, even when using a chemical mask at home!

22. How to Choose a Chemical Mask for Safety

Choosing the right chemical mask for safety involves matching the mask’s features to the specific hazards you will encounter. A wrong selection can lead to serious health risks, so understanding types, ratings, and fit is critical.

1. Steps to Choose the Right Chemical Mask:

- Identify the Chemical Hazard:

Know whether you are dealing with gases, vapors, particulates, or a combination. - Select the Proper Mask Type:

- Half-face masks protect nose and mouth (good for moderate exposure).

- Full-face masks also protect the eyes (needed for highly toxic or splashing chemicals).

- Check Certifications:

- Look for NIOSH-approved or equivalent standards.

- For industrial work, consider OSHA requirements.

- Choose the Correct Filter/Cartridge:

- Organic vapor cartridges for solvents, paints, pesticides.

- Acid gas cartridges for chemical manufacturing.

- Combination filters for mixed exposures.

- Assess Comfort and Fit:

- Adjustable straps.

- Silicone or soft-face materials.

- Conduct a fit test to ensure no leakage.

- Evaluate Durability and Maintenance:

- Reusable vs. disposable.

- Easy-to-replace filters and cleaning.

- Special Features (Optional):

- Anti-fog lenses.

- Communication devices for teamwork environments.

- Compatibility with safety goggles or hard hats.

Expert Tip:

Never assume a basic dust mask will protect you from chemical fumes — only specific chemical masks with the right cartridges provide effective protection!

23. Best Chemical Protection Mask for Painting

Painting, especially spray painting or working with solvent-based paints, exposes you to hazardous organic vapors, fine mists, and chemical particulates. A regular dust mask won’t protect you — you need a chemical protection mask specifically designed for painting.

1. What to Look For in a Painting Mask:

- Protection against organic vapors and fine particulates.

- Half-face or full-face design, depending on paint toxicity and application method.

- Comfort for long-term wear, with low breathing resistance.

- Compatibility with eye protection (for half masks) or built-in lens (for full-face masks).

2. Best Chemical Masks for Painting:

- 3M 6200 Half Facepiece Reusable Respirator

- Lightweight and cost-effective.

- Compatible with 3M 6001 Organic Vapor Cartridges.

- GVS Elipse P100 Respirator

- Compact and comfortable.

- Offers both particulate and vapor protection — great for detailed painting.

- 3M Full Facepiece 6800 Respirator

- Ideal for heavy-duty spray painting.

- Full-face coverage protects eyes from solvent splashes and mist.

Pro Painting Tip:

Always pair your mask with P100 filters combined with organic vapor cartridges for the best protection during painting projects!

24. Chemical Mask with Organic Vapor Cartridges

An organic vapor cartridge is crucial for filtering volatile organic compounds (VOCs) like solvents, gasoline, paint fumes, cleaning agents, and pesticide vapors. A chemical mask with organic vapor cartridges gives targeted protection against these specific chemical hazards.

1. Key Features of a Good Organic Vapor Mask:

- Approved for Organic Vapor Protection (NIOSH certification).

- Interchangeable cartridges to allow easy replacement.

- Comfortable facepiece with adjustable straps for long use.

- Good airflow design to prevent suffocation feeling.

2. Top Chemical Masks with Organic Vapor Cartridges:

- 3M 7502 Half Facepiece Respirator + 6001 Organic Vapor Cartridges

- Rugged yet extremely comfortable.

- Perfect for automotive, painting, and chemical handling.

- Honeywell North 7700 Series Half Mask with OV Cartridges

- Highly flexible silicone facepiece for enhanced comfort.

- Great seal and efficient vapor filtration.

- Moldex 7000 Series Reusable Respirator + Organic Vapor Filters

- Lightweight with a low-profile design.

- Good for tight spaces and long work hours.

Important:

Organic vapor cartridges must be replaced regularly, depending on exposure time and intensity — do not wait until you can “smell” the chemicals!

25. Chemical-Resistant Masks for Pesticide Spraying

Pesticide spraying involves direct exposure to highly toxic chemicals that can harm the lungs, skin, and eyes. A chemical-resistant mask for pesticide spraying must provide both vapor and particulate protection, and often full-face coverage is recommended.

1. Requirements for Pesticide Protection Masks:

- Organic vapor and particulate filtration combined (often OV/P100).

- Full-face protection (especially for high-concentration spraying).

- Durable, chemical-resistant material for harsh outdoor use.

- Lightweight and ventilated design to reduce heat buildup.

2. Best Masks for Pesticide Spraying:

- 3M 6000 Series Full Face Respirator + 60926 Multi-Gas/P100 Cartridges

- Broad-spectrum protection.

- Suitable for professional-grade pesticide spraying.

- Honeywell North 5400 Series Full Facepiece

- Highly affordable and rugged.

- Excellent choice for farmers, landscapers, and pest control workers.

- Draeger X-plore 5500 Full-Face Respirator

- Twin filter system for easy breathing.

- Superior field of vision.

Pesticide Spraying Tip:

Always decontaminate your mask after each use — pesticides can linger and corrode materials if not properly cleaned!

26. Full-Face Respirator for Chemical Spills

Chemical spills, especially involving volatile gases or toxic liquids, pose immediate and serious threats. A full-face respirator for chemical spills must offer the highest level of protection for the eyes, nose, and mouth against vapors, splashes, and airborne contaminants.

1. What Makes a Good Full-Face Respirator for Spills:

- Comprehensive protection against a wide range of gases, vapors, and particulates.

- Impact-resistant lens to shield against splashes.

- Secure, air-tight seal with easy adjustment.

- Quick donning capability in emergency situations.

- Option for SCBA (Self-Contained Breathing Apparatus) if needed for extreme spills.

2. Best Full-Face Respirators for Chemical Spills:

- MSA Ultra Elite Full-Face Respirator

- Industrial and emergency-ready design.

- Superior comfort and clear communication capability.

- Avon Protection FM12 Respirator

- Used by military and first responders.

- Protects against chemical, biological, and radiological agents.

- 3M FF-400 Ultimate FX Full Facepiece Respirator

- Soft silicone material with cool flow valve for easy breathing.

- Great for emergency chemical spill response teams.

Chemical Spill Emergency Tip:

If dealing with unknown or highly dangerous chemical spills, supplied-air respirators (SARs) or SCBA units should be used — not just air-purifying respirators!

27. Pros of Chemical Mask

- High-level chemical protection

- Durable construction

- Customizable fit

- Reusable options available

- Disposable options for convenience

- Full face protection available

- Variety of filter options

- Meets safety regulations

- Emergency-ready designs

- Lightweight versions available

- Replaceable filters

- Integrated communication systems (in some models)

- Wide field of vision

- Resistant to impact

- Chemical-resistant materials

- Comfortable for long wear

- Easy to maintain

- Versatile applications

- Trusted in industrial settings

- Cost-effective in the long run

28. Cons of Chemical Mask

- Can be expensive initially

- Filters require regular replacement

- Limited lifespan

- Can be bulky

- Heavy compared to simple masks

- Uncomfortable in hot environments

- Requires proper fit testing

- May cause skin irritation

- Restricted breathing at times

- Reduced hearing clarity

- Can fog up lenses

- Needs regular maintenance

- Training needed for correct use

- Not suitable for children

- Limited battery life in powered models

- Breakage risk if dropped

- Storage needs (cool, dry place)

- Not fashionable or discreet

- Limited facial hair compatibility

- May induce claustrophobia in some users

29. Top 10 Chemical Masks: Comparison Table

Here’s a detailed table featuring the Top 10 Chemical Masks based on expert reviews and safety standards (2024-2025 references included):

| Mask Name | Origin | Usage | Operation Duration | Best For | Price (USD) |

|---|---|---|---|---|---|

| 3M 6900 Full Facepiece | USA | Industrial, chemical spills, lab work | 6-8 hours per cartridge | Spray painting, solvents, emergencies | ~$250 |

| Honeywell North 7600 Series | USA | Industrial, agriculture | 8 hours per cartridge | Heavy chemical environments | ~$310 |

| MSA Advantage 3200 | USA | Chemical manufacturing, lab work | 4-6 hours per cartridge | Chemical processing plants | ~$270 |

| Avon Protection FM12 | UK | Military, hazardous material response | 8+ hours (CBRN rated) | Chemical warfare, emergency spills | ~$600 |

| Dräger X-plore 5500 | Germany | Industrial, agriculture | 6-8 hours | Pesticide spraying, heavy vapors | ~$250 |

| GVS Elipse P100 Half Mask | UK | Home, light industrial | 5-6 hours | Painting, pest control | ~$35 |

| 3M 7502 Half Facepiece | USA | Painting, solvents, DIY | 4-6 hours | Painting, spray work | ~$45 |

| Honeywell RU6500 Series | USA | Professional chemical handling | 6-8 hours | Laboratories, factories | ~$180 |

| Moldex 9000 Full Face Respirator | USA | Industrial, lab safety | 6-8 hours | Multi-chemical defense | ~$320 |

| MIRA Safety CM-6M Tactical Gas Mask | Czech Republic | CBRN emergencies | 8+ hours (CBRN rated) | Chemical warfare, disaster prep | ~$240 |

References:

- 3M Official Website (3m.com)

- Honeywell Safety Products

- MSA Safety (msasafety.com)

- Avon Protection (avon-protection.com)

- MIRA Safety (mirasafety.com)

1. Recommended Best Chemical Mask:

Avon Protection FM12

Why?

- Best-in-class protection against chemical, biological, radiological, and nuclear threats (CBRN).

- Used by military and emergency responders worldwide.

- Excellent operation time and extremely durable for extreme hazardous environments.

- Versatile usage: perfect for industrial, defense, and emergency chemical spill situations.

If you want a more affordable yet excellent choice for everyday industrial work or painting, then the 3M 6900 Full Facepiece is an amazing second choice.

30. Top 10 Chemical Mask Manufacturers

Here are the top 10 globally recognized manufacturers of chemical masks, known for their safety, innovation, and certifications:

| Manufacturer | Country | Specialties | References |

|---|---|---|---|

| 3M | USA | Full-face, half-face, industrial respirators | 3M Official |

| Honeywell Safety | USA | Industrial-grade masks, organic vapor cartridges | |

| MSA Safety | USA | Full-face masks for mining, chemical, and military use | |

| Dräger | Germany | Gas detection and respiratory protection systems | Dräger Official |

| Avon Protection | UK | Military-grade CBRN masks (e.g., FM12, C50) | Avon Protection |

| MIRA Safety | Czech Republic | Civilian and tactical chemical masks (e.g., CM-6M) | MIRA Safety |

| Sundström Safety | Sweden | Professional respiratory protection systems | Sundström Official |

| Scott Safety (now 3M Scott Fire & Safety) | USA | Firefighting and hazmat respiratory masks | |

| GVS Group | UK/Italy | Lightweight P100 masks for chemicals and particulates | GVS Group |

| Moldex-Metric | USA/Germany | Affordable, high-efficiency respirators | Moldex Official |

31. International Standards and Guidelines Governing Chemical Masks

Chemical masks must comply with strict international safety standards across various sectors. Here are key standards:

| Standard | Governing Body | Description | Reference |

|---|---|---|---|

| NIOSH (42 CFR Part 84) | U.S. National Institute for Occupational Safety and Health | Certifies respirators for workplace safety (filters, cartridges, full-facepieces) | NIOSH |

| EN 136, EN 14387 | European Committee for Standardization (CEN) | Standards for full-face respirators and gas/vapor filter performance | CEN EN Standards |

| OSHA 29 CFR 1910.134 | U.S. Occupational Safety and Health Administration | Mandatory respiratory protection programs in workplaces | |

| ISO 16900 Series | International Organization for Standardization (ISO) | Performance evaluation standards for respiratory protective devices | ISO Official |

| NFPA 1981, NFPA 1994 | National Fire Protection Association | Standards for chemical/biological incident response respirators | NFPA Standards |

| CSA Z94.4 | Canadian Standards Association | Selection, use, and care of respirators | CSA Group |

| GB 2626-2019 | Chinese Standardization | Chinese standard for respiratory protection (similar to NIOSH) | GB Standards |

32. International Statistics: Losses Due to Ineffective Use of Chemical Masks

1. 2 Million+ Occupational Illnesses Globally (Per Year)

- Over 2 million workers around the world suffer from occupational illnesses related to chemical exposure each year, many cases linked directly to inadequate or improper respiratory protection.

- Reference: World Health Organization (WHO)

2. 29% of Chemical-Related Workplace Injuries Linked to Poor Respiratory Protection

- According to the U.S. Bureau of Labor Statistics (BLS), nearly 29% of chemical exposure injuries in industrial workplaces are due to incorrect, missing, or inadequate chemical mask use.

3. $60+ Billion Annual Global Financial Loss

- Global industries face over $60 billion in financial losses each year due to illnesses and injuries caused by hazardous exposures — a large percentage due to improper or ineffective use of chemical masks and other PPE.

33. International Statistics: Achievements Due to Effective Use of Chemical Masks

1. 80% Reduction in Workplace Exposure Incidents

- Companies that implemented strict respirator programs and chemical mask training saw an up to 80% decrease in chemical exposure incidents, improving worker health dramatically.

2. 92% Drop in Respiratory Illnesses at Chemical Facilities

- A 5-year study at multiple chemical manufacturing plants showed a 92% reduction in respiratory illnesses among workers when certified chemical masks were properly selected, fitted, and maintained.

3. Zero Hazmat Fatalities During Emergency Chemical Spill Responses (2018–2022, USA)

- FEMA reports that certified full-face respirator use by emergency hazmat teams contributed to zero fatalities during major chemical spill responses in the United States between 2018 and 2022.

- Reference: Federal Emergency Management Agency (FEMA) Annual Reports

4. 65% Reduction in Chemical Inhalation Injuries Across Europe

- After enforcing the EN 14387 standards for chemical respirators across industries, Europe saw a 65% decrease in inhalation-related injuries.

- Reference: European Agency for Safety and Health at Work (EU-OSHA)

Summary Insight:

“Proper chemical mask usage isn’t just a recommendation — it is the difference between preventable illness and workplace safety excellence worldwide.”

34. Summary of Chemical Masks

1. What They Are:

Chemical masks (or chemical respirators) are specialized personal protective equipment (PPE) designed to filter hazardous airborne chemicals, gases, vapors, and particulates.

2. Purpose:

- Protect respiratory tract and lungs from chemical exposure.

- Prevent acute poisoning and chronic illnesses from inhaling harmful substances.

3. Components:

- Facepiece, filters/cartridges, inhalation/exhalation valves, head harness.

4. Types:

- Half-face respirators

- Full-face respirators

- Powered air-purifying respirators (PAPRs)

- Self-contained breathing apparatuses (SCBAs)

5. Key Selection Factors:

- Type of chemical hazard (organic vapors, acid gases, particulates)

- Duration of exposure

- Environmental oxygen levels

- Fit and comfort

6. Importance:

Proper selection, maintenance, and use of chemical masks dramatically reduce occupational illness, improve workplace safety, and save lives.

7. Top Manufacturers:

3M, Honeywell, MSA, Dräger, Avon Protection, MIRA Safety, Sundström Safety, Scott Safety, GVS Group, Moldex-Metric.

8. Standards:

Governed by global safety bodies like NIOSH, OSHA, CEN (EN standards), ISO, NFPA, CSA, and GB.

9. Global Impact:

When properly used, chemical masks significantly lower health risks, reduce injuries, and cut billions in financial losses across industries worldwide.

35. FAQs

1. Choosing the right chemical mask for maximum safety

Choosing the right chemical mask depends on the type of chemical exposure, the environment, and the duration of use. Look for masks that meet recognized safety standards (like NIOSH, OSHA, or EN certifications), are compatible with the chemicals you’ll encounter, and offer the correct filtration type (such as gas/vapor cartridges, P100 filters, or combination units). Comfort, fit, and ease of maintenance are also key factors to ensure maximum safety during prolonged use.

2. Protect yourself from toxic fumes with a certified chemical mask

Certified chemical masks are specifically tested to block or neutralize hazardous gases, vapors, and airborne particles. By using a mask certified by trusted organizations (such as NIOSH or CE), you can ensure it has passed rigorous testing for filtration efficiency and chemical resistance, providing reliable protection against toxic fumes in industrial, laboratory, or emergency settings.

3. Chemical masks designed for industrial and laboratory environments

Chemical masks for industrial and laboratory use are built to withstand high concentrations of hazardous substances. They typically feature durable construction, adjustable straps, replaceable filters or cartridges, and materials resistant to chemical degradation. These masks protect against specific threats like acid vapors, solvent fumes, or toxic particulates, making them essential for chemical plants, research labs, and manufacturing facilities.

4. How chemical respirators prevent hazardous inhalation

Chemical respirators work by either filtering out harmful particles and vapors from the air or by supplying clean air from an independent source. Filtering respirators use specialized cartridges that absorb or neutralize chemicals, while supplied-air respirators deliver clean, breathable air through hoses connected to a safe air source. This barrier system prevents hazardous substances from entering the respiratory tract, thus protecting the lungs and overall health.

5. Essential features to look for in a chemical protection mask

When selecting a chemical protection mask, look for these essential features:

- Certification (NIOSH, CE, etc.) for chemical protection

- Replaceable and compatible filters or cartridges

- Secure, adjustable fit for a tight seal

- Durable and chemically resistant materials

- Clear, anti-fog face shield (for full-face masks)

- Lightweight design for comfort during long use

- Easy maintenance and cleaning options

- Compatibility with other personal protective equipment (PPE)

6. Understanding different types of chemical respirators

Chemical respirators come in several types, each suited for different exposure levels and hazards:

- Air-Purifying Respirators (APRs): Use filters or cartridges to remove chemicals from the air; best for environments where oxygen levels are safe.

- Powered Air-Purifying Respirators (PAPRs): Use a battery-powered blower to pull air through filters; offer more comfort for long-term use.

- Supplied-Air Respirators (SARs): Provide clean air from an external source via hoses; used where contaminants are too high for filters.

- Self-Contained Breathing Apparatus (SCBA): Carry their own air supply; essential for highly toxic or oxygen-deficient environments, such as chemical spills or fires.

7. When to replace filters in your chemical mask

Filters and cartridges should be replaced based on manufacturer guidelines, workplace standards, or when you notice signs like:

- Increased breathing resistance

- Smell, taste, or irritation from contaminants

- Expired service life indicated on the cartridge

In high-risk settings, it’s often recommended to follow a strict change schedule (e.g., daily, weekly) even if no signs of breakthrough are noticed.

8. The importance of a proper fit in chemical respiratory protection

A proper fit is critical because even a small leak can allow hazardous chemicals to bypass the filter and be inhaled. Fit testing ensures that the mask seals tightly to your face, preventing exposure. Regular fit tests (both qualitative and quantitative) and user seal checks before each use help maintain the highest level of protection.

9. Protective equipment for chemical exposure emergencies

In chemical emergencies, you need comprehensive PPE, including:

- Full-face chemical respirators or SCBAs

- Chemical-resistant suits (Tyvek®, PVC, or rubberized materials)

- Chemical-resistant gloves and boots

- Eye and face protection (goggles or full-face shields)

- Emergency eyewash stations and decontamination showers nearby

Quick access to proper PPE can dramatically reduce injury during spills, leaks, or accidents.

10. Best practices for wearing and maintaining a chemical mask

- Always inspect the mask and filters before each use for damage or wear.

- Ensure the correct cartridge or filter is installed for the hazard.

- Perform a user seal check every time you put the mask on.

- Clean the mask regularly according to the manufacturer’s instructions.

- Store the mask in a clean, dry place away from direct sunlight and chemicals.

- Replace filters/cartridges on schedule and track expiration dates carefully.

11. Does a chemical mask need a fit test?

Yes, a chemical mask (especially tight-fitting types like half-face and full-face respirators) requires a fit test. This ensures the mask forms a proper seal against the wearer’s face, preventing chemical vapors, gases, or particles from leaking into the breathing zone.

12. Regulations of fit test for chemical mask

Fit testing for chemical masks is regulated primarily under:

- OSHA 29 CFR 1910.134 (United States Occupational Safety and Health Administration Respiratory Protection Standard)

- NIOSH (National Institute for Occupational Safety and Health) guidelines

- ANSI Z88.10 (American National Standards Institute for Respirator Fit Testing) These regulations require employers to conduct fit testing before initial use, whenever a different respirator facepiece is used, and when physical changes in the wearer could affect fit (e.g., significant weight change, dental work, facial surgery).

13. Frequency of testing chemical mask

A chemical mask fit test must be conducted:

- Annually (every 12 months at minimum)

- Whenever a different make, model, style, or size of respirator is used

- After any physical change in the wearer that could affect mask fit (weight gain/loss, facial surgery, significant dental changes, etc.)

14. Chemical mask usable time from manufacturing date

The usable time (shelf life) of a chemical mask (including its cartridges and filters) depends on the manufacturer, but generally:

- Facepieces (mask body): Often up to 5–10 years if stored properly.

- Cartridges/filters: Typically 3–5 years from the manufacturing date if unopened and stored according to specifications. Important: Once chemical cartridges are opened and exposed to air, their service life can be hours to weeks, depending on the chemical exposure and usage conditions. Always follow the manufacturer’s expiration date and guidelines.

15. Requirements for chemical mask

Key requirements for chemical masks include:

- NIOSH approval (or other national certification)

- Proper fit and seal (confirmed by fit testing)

- Correct selection based on the chemical hazard (different cartridges for different chemicals)

- Maintenance and cleaning according to manufacturer’s instructions

- Proper storage (cool, dry place away from direct sunlight or contaminants)

- Training for users on donning, doffing, and maintenance

- Inspection before each use for damage, wear, or expired parts

16. Limitations of chemical mask

Some common limitations of chemical masks:

- Not effective in oxygen-deficient atmospheres (less than 19.5% oxygen)

- Limited by cartridge/filter capacity – cartridges can become saturated without obvious signs

- Requires proper fit – facial hair or improper wearing compromises protection

- Does not protect against all types of airborne hazards (e.g., very high concentrations may require SCBA)

- Reduced effectiveness if damaged or poorly maintained

- User discomfort – extended wear can cause fatigue, heat buildup, and breathing resistance

17. How to conduct fit test of chemical mask

Fit testing a chemical mask can be done by two methods:

- Qualitative Fit Test (QLFT):

- A pass/fail test that relies on the wearer’s senses (taste, smell, or reaction to an irritant) to detect mask leakage.

- Common test agents: saccharin (sweet taste), Bitrex (bitter taste), isoamyl acetate (banana smell), or irritant smoke.

- Steps:

- Wear the chemical mask correctly.

- Place a hood over the head.

- Spray the test agent into the hood.

- Perform a series of exercises (talking, moving head, bending) while checking for leaks.

- If the wearer senses the agent, the mask fails.

- Quantitative Fit Test (QNFT):

- Uses a machine (like a PortaCount®) to measure the actual amount of leakage into the respirator.

- Steps:

- Attach a probe or adapter to the mask.

- Connect the mask to the machine.

- Wear the mask and perform a series of exercises.

- The machine calculates a “fit factor” that must meet or exceed minimum requirements.

18. How to wash a chemical mask

To wash a chemical mask (the facepiece only, never wash cartridges or filters):

- Disassemble the mask: remove cartridges, filters, and any detachable parts.

- Prepare a mild cleaning solution: warm water (not hot) with a mild detergent or use manufacturer-approved wipes.

- Gently scrub the facepiece (including straps) using a soft brush or cloth.

- Rinse thoroughly with clean, warm water to remove all soap.

- Sanitize if required: use a disinfectant recommended by the manufacturer.

- Air dry the parts in a clean, non-contaminated area.

- Inspect the mask after drying for any damage or wear before reassembling.

19. How many times can a chemical mask be washed

- A chemical mask (the reusable facepiece) can typically be washed hundreds of times if done properly.

- However, it should be replaced if:

- The material shows signs of wear (cracks, stiffness, tearing).

- It no longer maintains a proper seal.

- With good maintenance, a high-quality reusable chemical mask can last several years.

20. How many times a chemical mask is reusable

- The facepiece of a chemical mask is designed to be reusable many times — often for years if properly maintained.

- Cartridges and filters, however, are NOT reusable once their capacity is exhausted or after exposure to certain chemicals or moisture.

- Always replace cartridges according to:

- Manufacturer’s instructions.

- End-of-service-life indicators (ESLI) if available.

- Scheduled change programs if required by workplace safety rules.

- Summary:

- Facepiece: Reusable multiple times (until worn out).

- Cartridges/filters: Limited-use, replace after use or per expiration guidelines.

36. Conclusion

A chemical mask is an indispensable part of personal protective equipment (PPE) for anyone working around hazardous chemicals, gases, and toxic fumes. Whether it’s an industrial chemical mask for manufacturing plants, a gas mask for chemicals for emergency responders, or a chemical warfare mask for defense forces, choosing the right mask can be the difference between life and death. As technology continues to evolve, these lifesaving devices are becoming more efficient, smarter, and accessible — ensuring better chemical inhalation protection for all.

Please Write Your Comments